-

Customization

-

Service

-

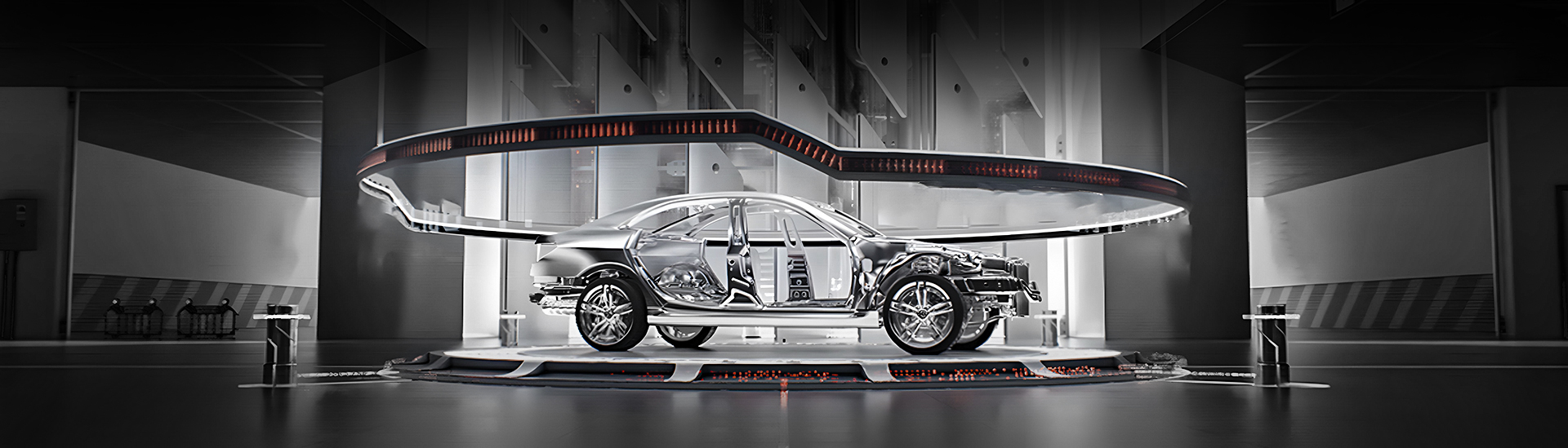

Quality

-

Production Capacity

-

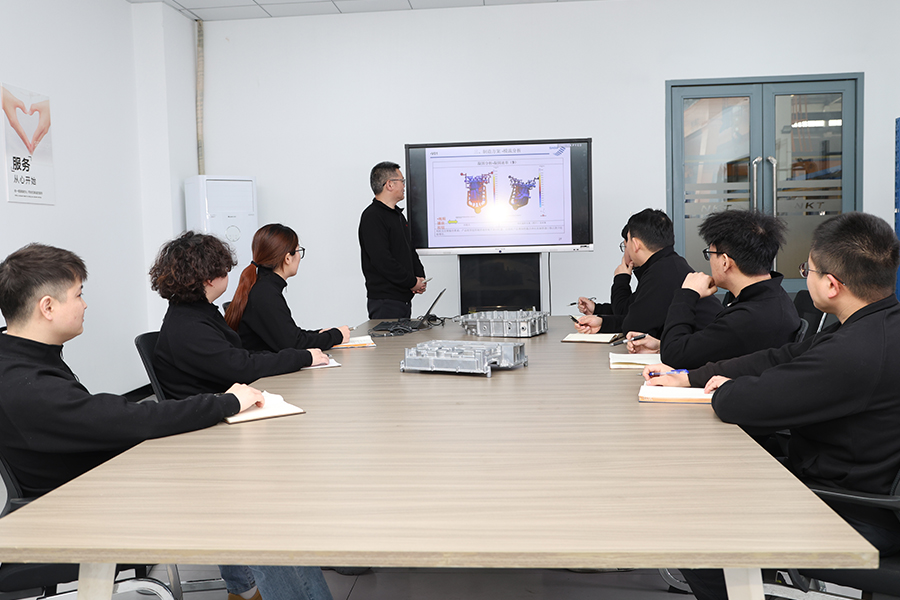

Customization

The senior design team can provide customers with early casting design, DFM, mold design, mold flow analysis, and process support services.

-

Service

Provide technical service and support from casting development to mold end. Provide model testing service. 24-hour after-sales service telephone, respond in time within 2 hours. Provide trial small batch proofing within 50 pieces.

-

Quality

We have professional testing personnel and the advanced testing equipment in the industry to ensure product quality.

-

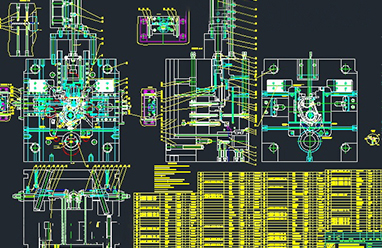

Production Capacity

Our annual output of more than 300 sets (pay) of various high-precision die-casting dies, which can meet the needs of customers with different purchasing quantities; And constantly refine the technological process to meet the delivery problem of customers.

English

English 中文简体

中文简体